Keeping the base of installed lifts in perfect working order represents the main occupation of many lift companies in Europe and is increasing in the rest of the world. According to the latest data published by the European Lift Association in 2019, there are more than 6,150,000 lifts installed there, many with more than fifteen years of service. The modernization activity of these elevators has generated in the course of 2018 a turnover of more than 1,629 billion euros. For a better orientation in this important market, I propose a classification of the main elevator modernization activities in five levels, which respond to different requirements.

Tier 1: Component Kit

A first level of modernization, regarding the primary objective of maintaining the efficiency of the installation, is the replacement of an established series of worn components, grouped in specific packages, according to the type of component. This activity has many similarities to maintenance interventions on existing lifts, with the replacement of some worn or malfunctioning components. However, the replacement of a series of components indicated by the manufacturer at defined intervals and within a single operation offers some advantages to both the lift company and its users:

Interventions are planned for the times and times of least use of the facility and when they cause the least inconvenience to users;

The elevator company does not incur any additional costs due to the urgency of the elevator being out of service; components can be provisioned in advance and appropriately modulate the workload of the technical team that will perform the tasks.

The complete replacement of all worn components, for example in the case of elevator doors, makes it possible to correctly restore the initial level of operation and avoid successive interventions on non-replaced components, which in a short time can reach the end of their useful life, causing the elevator to stop.

Level 2: Replacement of a component

The second level identifies the replacement activity of a specific elevator component. Typically, such activities are concentrated on components that add more value to the elevator. In particular, the main candidates are the car door operator, the reduced or gearless tractor, parts of the interior of the car and other aesthetic components (landing door panels, mirror, car ceiling and lighting).

These replacements are normally due to a breakage of the component itself, to the addition of current details to the existing elevator; to the improvement of accessibility to the elevator (a typical example is the replacement of swing landing doors with automatic doors or the replacement of a manual car door with an automatic one), or to some requirement by the users of an aesthetic improvement of components in sight.

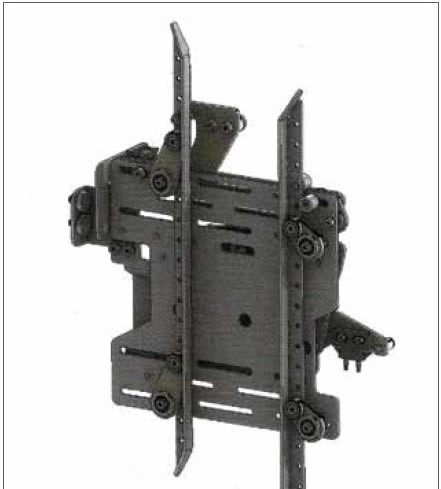

To facilitate this activity, component manufacturing companies have developed specific products for modernization, characterized by:

Compact dimensions to facilitate installation in existing lifts with limited space;

Easy interface with existing components (for example: elements to connect the new automatic car door with the existing swing landing door).

Availability of solutions designed especially for the replacement of a specific original component, which also includes interface elements, fixing solutions and design and installation instructions. Such solutions drastically reduce on-site adaptations to the existing elevator and construction site, reducing complexity and installation times.

The limitations of this level of modernization approach lie in the fact that user satisfaction is often tied to multiple factors. Modernizing an elevator with a state-of-the-art cabin door operator brings tangible benefits, which, however, for the end user may be frustrated by the presence of swing doors, which limit accessibility, or by old indicators that are difficult to read or aesthetically pleasing. old-fashioned

Tier 3: Upgrade Kits

For this reason, a good part of the modernization work in Europe's elevators is being oriented towards a third level of modernization: the adoption of the modernization package with more components, which, in the face of a moderately more complex job and a stoppage of the elevator, little more extensive in time, they allow to greatly increase the performance of the modernized elevator in terms of operation, level of safety, response to new regulations that came into force, energy efficiency, level of accessibility, user experience and user satisfaction.

Some examples are the replacement of the maneuver control and all the indicators and buttons, which improve the user experience; or the replacement of the pulley with a state-of-the-art gearless motor controlled by an inverter, which significantly reduces the installation's energy consumption. This level also includes aesthetic interventions such as the replacement or lining of the cabin walls or the renovation of the landing doors. We can also present here the regulatory compliance interventions, including the installation of UCM (Uncontrolled Car Movement) solutions in an existing elevator, which updates it according to the latest regulations by introducing control of the position of the car with respect to the level of the floor when the doors are open: a fundamental element to further increase the safety of installations, already required by the local regulations of some European countries, including Germany, not only for new installations, but also for the scope of significant interventions of modernization.

Level 4: complete replacement of the elevator

Finally, in particular cases or for installations with a significant amount of service, the modernization extends to the entire installation, almost always safeguarding only the guides and installing a new complete elevator in the existing passageway. Such interventions find their meaning in the context of a requalification of historic buildings or their own intended use. The availability of complete lifts with the upper part of the run and the pit reduced, dimensionally adaptable to smaller existing passageways, combined with very compact components, allows to obtain lifts with performance perfectly aligned with the best new lifts, even in non-optimal installation situations. , such as those in confined spaces.

Level 5: The service

To get the best out of these retrofit kits, it's important to rely on a partner that provides an adequate level of support throughout the entire retrofit process.

That is why we speak of a fifth essential level for elevator companies to obtain the best results from their own modernization activity: service. In addition to providing the components and kits, the best manufacturer offers:

On-site inspection and services and survey of the elevator to be modernized, to adequately verify the situation and any specific problems;

Engineering services, to find the most appropriate technical solution for each lift to be modernized, complete with the necessary accessories and adaptations;

Logistics services that allow, in a short time, the provisioning of the necessary components;

Training services, to facilitate the activity of employees and transfer the best modernization practices;

Post-sale services, to quickly resolve any problem on the construction site.

Such services are essential to be able to conduct a modernization activity with precise and predetermined times and costs and to obtain maximum user satisfaction.

Article taken from “How 5 works”, Volpe Editore, 2019.